√操作简单、换线便利Simple programming,quick changeovers

√高效率、高质量、高精度High efficiency,high quality,high precision

√智化能,具有自动检查条a码功能Intelligentialize and can check the barcode automatically

√运作成本低Lowest running cost

√通用性强Universal

√先进的油墨管理系统Advanced fluid management

√自动清洁喷头功能Practical auto cleaning printhead function

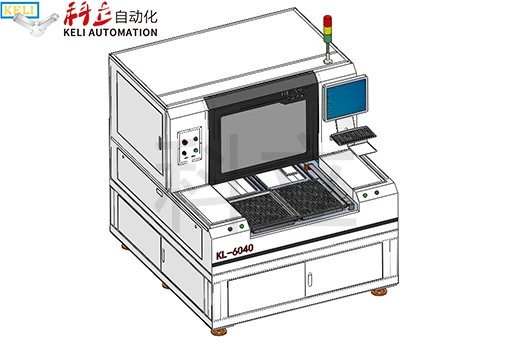

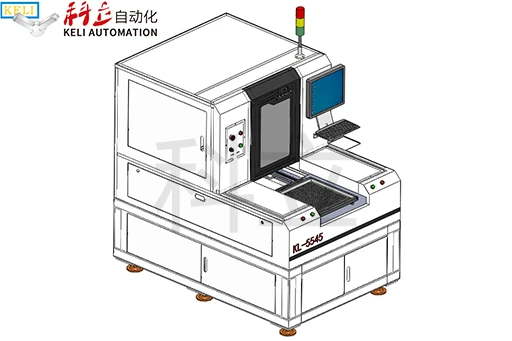

科立KL-7900是一款全自动PCB喷码机,可配备法国依玛士Markem Imaje、英国LINX等质优喷码头,并结合科立自动化工艺,喷印的效果具有更高的可靠性、更低的成本、简单易用,同时可在线操作,省人省事省钱,是电子企业全自动升级的较好选择。具体特点如下:

KL-7900 that KELI develops is an automatic PCB Ink Jet Printer,which equips with high-quality printhead from Markem Imaje in Franceor Linx in UK,and combines with KELI automation technology,the printing effect has higher reliability,lower cost,and easy to control and itcan be in-line operation,save time and manpower,it is the best choice to the company automation upgrading.The specific features are as

操作简单、换线便利 Simple programming,quick changeovers

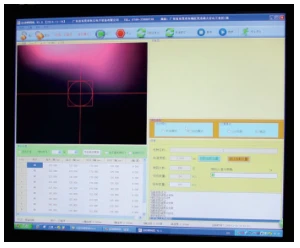

A.本机采用电脑控制,人机介面简单,操作易学易懂。

Bright display with WYSIWYG for easy operation.

B.快速换线Quick changeovers:

√程序控制Programming control..

√全自动调节Automatic adjustment.

√换线只需更换程序Change line only need to update the program.

高效率、高质量、高精度High efficiency,high quality,high precision

√高效率:

完成一个产品,只需8秒左右(2联板)

High efficiency:only needs 6-8 seconds tofinish one product(2 joint boards)

√高质量:喷出的条码清晰美观,形状规范,不会出现贴歪及没贴牢的现象。

High quality:the printed barcode clear andshaped,comparing with labelling machine,there has no risk of paste distortion orinsecure.

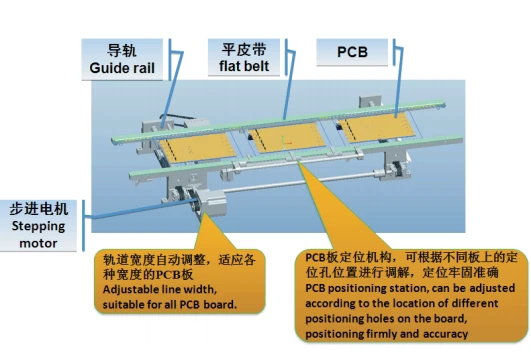

√高精度:采用伺服马达、步进马达、滚珠丝杆、直线导轨传动,定位准确。

High precision:Driving with Servo motor,stepping motor,screw rod and guide rail etc,more accuracy.

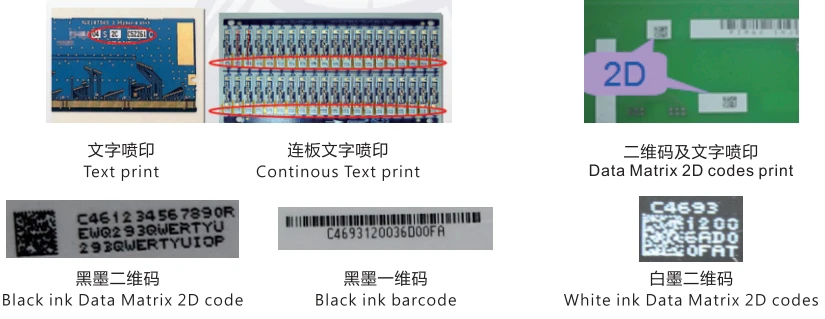

科立全自动喷码机可喷效果:Printing text type:

√可喷多达3行文字、微标、条形码、一维码、二维码和OCR码等。

It can print 3 lines of text,logos,barcodes,1D barcodes,Data Matrix 2D code and OCR codes etc.

√加装旋转机头,可按“米”字形轨迹进行喷码。

Rotating head application to support print in "*"shape.

智化能Intelligentialize

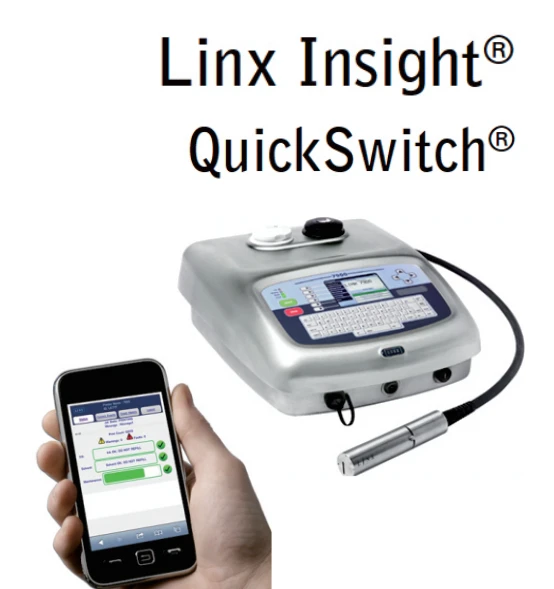

√新型Insight®可以让您用智能手机进行远程监控,并从PC下载和上传信息,有助于防止喷码错误。

Up-to-date Insight to monitor remotely from smart phone,plus download or upload information from PC,for mistake-free printing on products.

√QuickSwitch®PIus软件可以让您用条形码扫描器快速更改标码。

Smart QuickSwitch@Plus software to use barcode scanner to quickly change from standard code.

√使用标准USB端口可以让您便捷地在喷码机之间传输消息。

Easy transfer message between printers with a standard USB port.

√CCD自动找MARK点定位。

Automatic visual MARK point finding and coordinate calibration function.

√2D条码、OCR码识别、读取及验证。

Data Matrix 2D codes,OCR code recognition,reading and verification.

运作成本低、无隐性成本Lowest running cost and no hidden cost

√节省标签成本:用喷码代替了贴标,节约了标签耗材费用和贴标人力成本,特别是现在人力工资不断上涨。

Saving:Use the printer to replace the labelling machine,it saves the cost comparing using label machine which with the cost about the label and labour cost.

√可擦试重喷:喷的码在过锡炉前无论多久都可以用酒精擦除。

Erasable:Printed code can be erased no matter how long before soldering.

√较低人力负担:一人可负责4~6条产线,作业员工作负荷也较大降低。

One person easy to take care 4-6 production lines.

√定期维修时更换的零件极少,没有需要更换的昂贵墨水系统配件

Minimal parts changed at scheduled services,no expensive ink system assemblies to replace.

通用性强Universal

√适应所有PCB板需要条码的产品。

Suitable for all PCB board.

√可支持单机或连线作业。

Can support in-line or off-line.

先进的油墨管理系统Advanced fluid management

√使用SureFil训®系统实现快速防误注液。

Excellent SureFillR system to achieve faster mistake-proof refills.

√无污染,无浪费,无错误颜色喷码现象。

No mess,no waste,no mistake fluid cartridge delivery system.

√换耗材不停机,线上即时更换油墨/溶剂。

Chang the consumables no need stop the printer,replace ink on line.

自动清洁喷头功能Practical auto cleaning printhead function

√使用独特的FullFlush®系统每次关机时自动各方面清洁喷头和导管,即使长时间关机,确保无故障启动和停止。

Unique FullFlush system ensures reliable startups.Automatic and thorough cleaning of the printhead and conduit at every start-ups,even after extended shutdowns.

Functional Specifications 技术参数

| 参数Specification | 参数Specification |

| PCB尺寸PCB size | L100 x W50~L 300 x W300mm |

| PCB厚度PCB thickness | 0.8~3.0mm |

| 喷码头旋转Printhead rotation | 0- 180° |

| 较大运行范围Max travel area | L 400 x W300mm |

| 传送带宽度Conveyor width | 60-300mm |

| Motor of Axes控制轴数 | 3 Axes(AC Servo motor) |

| 导轨Gride rail | 中国台湾.上银直线导轨Taiwai linear guide rail of siver |

| 丝杆Screw rod | 精密研磨滚珠丝杆Precision grinding ball screw |

| 定位精度Positioning accuracy | 土0.02mm |

| 伺服系统Servo system | 松下AC伺服电机(400W) Panasonic AC servo motor |

| 控制主机Control host | 研华P4工控机Industrial control computer |

| 编程模式Programming | 手动编写、自动画框、CAD数据导入自动对应元件库 Automatic programming, manual programming, CAD input |

| 摄像头Camera | 全彩色高速智能数字相机High speed intellectualized digital color camera |

| 视觉范围Range | FOV: 25* 20mm |

| 视觉定位功能Visual positioning function | 2个Mark点定位2 mark points positioning |

| 电压Voltage | 单相电Single phase: 220VAC土10%,50/60HZ |

| 耗电量Power consumption | 2000W |

| 气压Air supply | 正压力Positive pressure 4.0-7.0kg/cm2 |

| 机器尺寸External dimension | L1186 x W1086mm x H1516mm(不包括信号灯Singal lamp not included) |

| 重量Weight | 900kg |

| 喷码头Printhead | 法国Markem Imaje 或英国Linx 7900 Ultima |

| 喷印每秒较大字符数Max characters per second | 2222个/pcs |

| 可喷印条码类型Printing type | 可喷多达3行文字、微标、条形码、一-维码、二维码、OCR码等 |

| It can print 3 lines of text, logos, barcodes, 1D Barcodes, Data Matrix 2D codes and OCR codes etc. | |

| 条码识别Barcode recognition | 一维码、二维码、OCR码等1D Barcodes, Data Matrix 2D codes, OCR codes etc. |

| 喷印字体高度Printing text height | 1.8~7.8mm |

| 喷码速度Printing speed | 100-800mm/s |

注:以上参数为标准配置,若有特殊需要的可根据客户要求改进定制技术参数若有改变,恕不另行通知,较终解释权归广东东莞市科立自动化有限公司所有。