技术参数

KL-5100

In Line Tester& Testing line

在线测试仪

在线ICT测试仪 In-Circuit Tester

在线FCT测试仪 Functional Circuit Tester

在线测试线 In line testing line

√ 操作简单 Easy operatio

√ 专业高效 Professional and efficient

√ 在线式设计 In line design

被测器件技术指标 Test Parameters | |

测试点数 Test dots | 配置点数Stand dots: 320 点 dots ⼤点数Max dots: 1792点dots 开关板Switch board:64点/块 64dots/pcs |

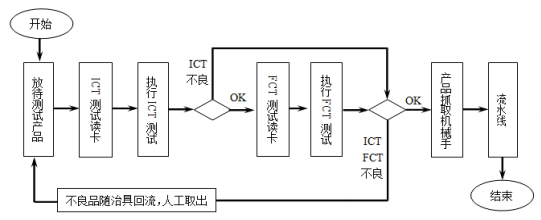

测试步骤 Test step | 扫PCB板条码→ ICT测试→ FCT测试 Scan→ ICT test→ FCT test |

测试时间 Test cycle | 测试时间跟PCB板测试项⽬有关 It has the difference depends on testing item. |

ICT测试范围 ICT testing items | 开/短路测试、电阻测试、电容测试、电感测试、隔离测试、电压测试、跳线测试、⼆极管测 试、稳压管测试、频率测试、晶体管导通测试、晶体管β值测试、电容极性、电压感应测试等。 Open/short Circuit testing, Resistance testing, Capacitance testing, Inductance testing,Isolation testing, Voltage testing, Jumper testing, Diode testing, Zener diode testing, Frequency testing, Transistor conduction testing, Transistor beta value testing, |

FCT测试范围 FCT testing items | 电源效应及负载效应测试、静态测试、在线电压调整测试、过载保护测试、过功率保护测 试、过电压保护测试等。 Power effect and load effect testing, Static testing, Online voltage adjustment test, |

机械技术指标 Machine Parameters | |

电脑系统 Operation system | Windows XP操作系统 Windows XP,I/O通讯软件 I/O communication software |

传送⽅向 Transfer direction | 从左到右Left to right 从右到左Right to left |

Conveyor | 100-300mm |

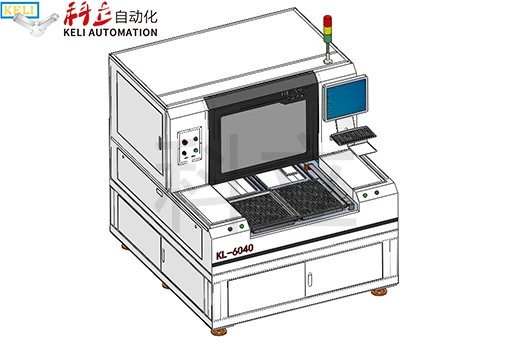

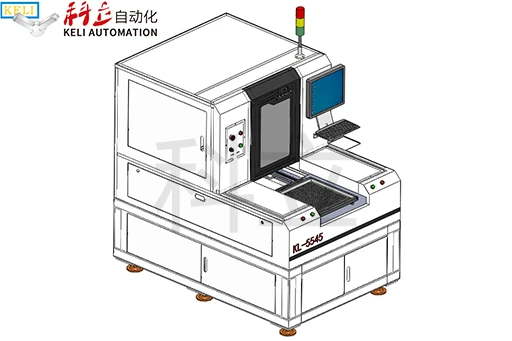

可测PCBA板(载具)⼤尺⼨ PCBA size | 50*50mm--350*450mm |

PCBA板厚度 PCBA thickness | 1-4.0mm |

PCBA板重量 PCBA weight | ≤1.5kg |

轨道⾼度 Orbit distance from ground | 900±20mm |

功率 Power | 200V-240VAC |

功率频率 Frequency | 50Hz/60Hz |

⼯作⽓压 Pressure | 4 0-6 0MPa |

| 压床⾏程 Press travel | 150mm±5mm 可调整 adjustable |

注:以上参数为标准配置,若有特殊需要的可根据客户要求改进定制技术参数若有改变,恕不另行通知,较终解释权归广东东莞市科立自动化有限公司所有。

广东东莞10市00*9科00*立1700自mm动化设备有限公

√ 自动化程度高 Highly automated

√ 稳定性好,方便耐用 Better stability, convenient and endurable √ 更换治具简单快捷 Easy to change the fixture

外观尺⼨ External Dimension

科⽴KL-5100在线测试仪是科⽴为满⾜电⼦产业中各类产品⾃动化测试需求 ,特推出 ⼀ 款在线式的⾼效测试仪。不但测试精度⾼ 、寿

KL-5100 Inline Tester that KELI develops is to help the electronic manufactures for the automatic test, it not only with high accuracy, long service life, but also with flexible expansibility, can be easily connected with the automatic production line. The specific features are as follows:

操作简单 Easy operation

操作简单 Easy operation

√ 操作简单、安全,同时⽅便维修排除故障。

Easy to use, and easy troubleshooting.

√ 完善的⼈机⼯程及故障报警系统。

Perfect man-machine engineering and safety protection, automatic fault alarm system.

√ ⽅便的调试控制界⾯,⽤⼾可以作⼿动的模拟测试。

专业⾼效 Professional and high efficiency

专业⾼效 Professional and high efficiency

√ 测试软件采⽤多线程模式,提升测试效率,单次测试16PCS/治具,UPH=2200。

Multithreading mode test system application to improve the test efficiency significantly, one single fixture can support 16PCS PCBA with the UPH more than 2200.

√ 可单独使⽤ICT或FCT功能测试,也可⽤ICT+FCT联合测试。

Can support the test item of ICT, FCT or ICT & FCT joint testing.

√ 可⾃⾏编写测试项⽬,实现不同型号的产品测试。

Can write test items to achieve different types of product testing.

√ 独⽴记录每⼀通道不良测试数据,便于对治具状况作分析判断。

Recording each channel independent adverse test data, which is convenient for analysis and judgment of fixture status.

√ 完整测试报表及测试统计数据,测试完成后数据可⾃动储存,有利于⽤⼾作质量分析管控。

Integrity test report and statistics, can be automatically stored after testing, to help the user for quality analysis and control.

√ 测试完成后,⾃动给产品放电,充分保护产品。

Automatic product discharge after testing, full products protection.

√ 界⾯上分别显⽰ICT与FCT测试结果,直观清晰。

Display ICT and FCT test results separately, intuitive and clear.

√ 模块化的结构设计,⽅便维护。

Modularization structure design, convenient maintenance.

√ 应⽤IC Clamping Diode技术,检测IC脚位故障及焊接不良。

Using IC Clamping Diode technology application for the IC pin and bad welding fault detection.

√ 输出信号频率可选⼀兆赫,对⼩电容与⼩电感的测试效果特佳。

The frequency of the output signal has optional of one MHz, better results for small capacitance and inductance.

在线式设计 In line design

在线式设计 In line design

√ 在线测试,PCBA板测试完成后,良品和不良品⾃动分类和收集⾃动下料到流⽔线上,减少⼈⼒操作,提升品质可靠性。

In line conveyor, the product and the defective product automatic classification and collection after the testing,automatically connect with the production line, reduce manpower, improve the quality of reliability.

√ 传送轨道宽度可调节适⽤不同宽度的PCB。

Transmission line width and conveyor direction can be adjusted to suitable for different width of PCB.

√ 可根据需求,加装Datalogic激光扫描仪,能识别⼀维码和⼆维码等。

扩展灵活,⾃动化程度⾼ Flexible expansibility, highly automated

扩展灵活,⾃动化程度⾼ Flexible expansibility, highly automated

√ 可组成嵌⼊式⾃动化⽣产线可低成本快速组建测试⽣产线,兼容市⾯上所有送板机、收板机,以低成本实现整条产线⾃动化。 It can be compatible with loading and uploading machine, to achieve the full autoline with low cost.

√ 扩展灵活,可以在⼯作站中加⼊⾃动喷码机、点㬵机、镭雕机、分板机、插件机等⾃动化设备。

Flexible expansibility, can be connect with additional machine, such as printing machine, dispenser, laser engraving machine, router and

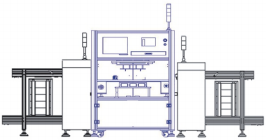

A: ⾃动测试站 Automatic test station

⾃动上板机Auto-loading Machine 合格品收板机Auto-unloading Machine

合格品收板机Auto-unloading Machine

B: 嵌⼊⾃动化⽣产线 Embedded automatic testing line

波峰焊 Wave soldering system | ICT&FCT测试 ICT&FCTtesting | ⾃动点㬵机 Auto dispenser 可选站 | ⾃动分板机 PCB Router 可选站 |